Collaborative robotics, AI-powered machine vision and food packaging automation took center stage at our robotics and automation event, held on May 22, 2025, at Probot’s facility in Kempele. Organized in collaboration with Murri Oy, the event brought together industry experts, customers and students to explore the practical applications of modern technology.

Collaborative Robots and SafeSkin in Action

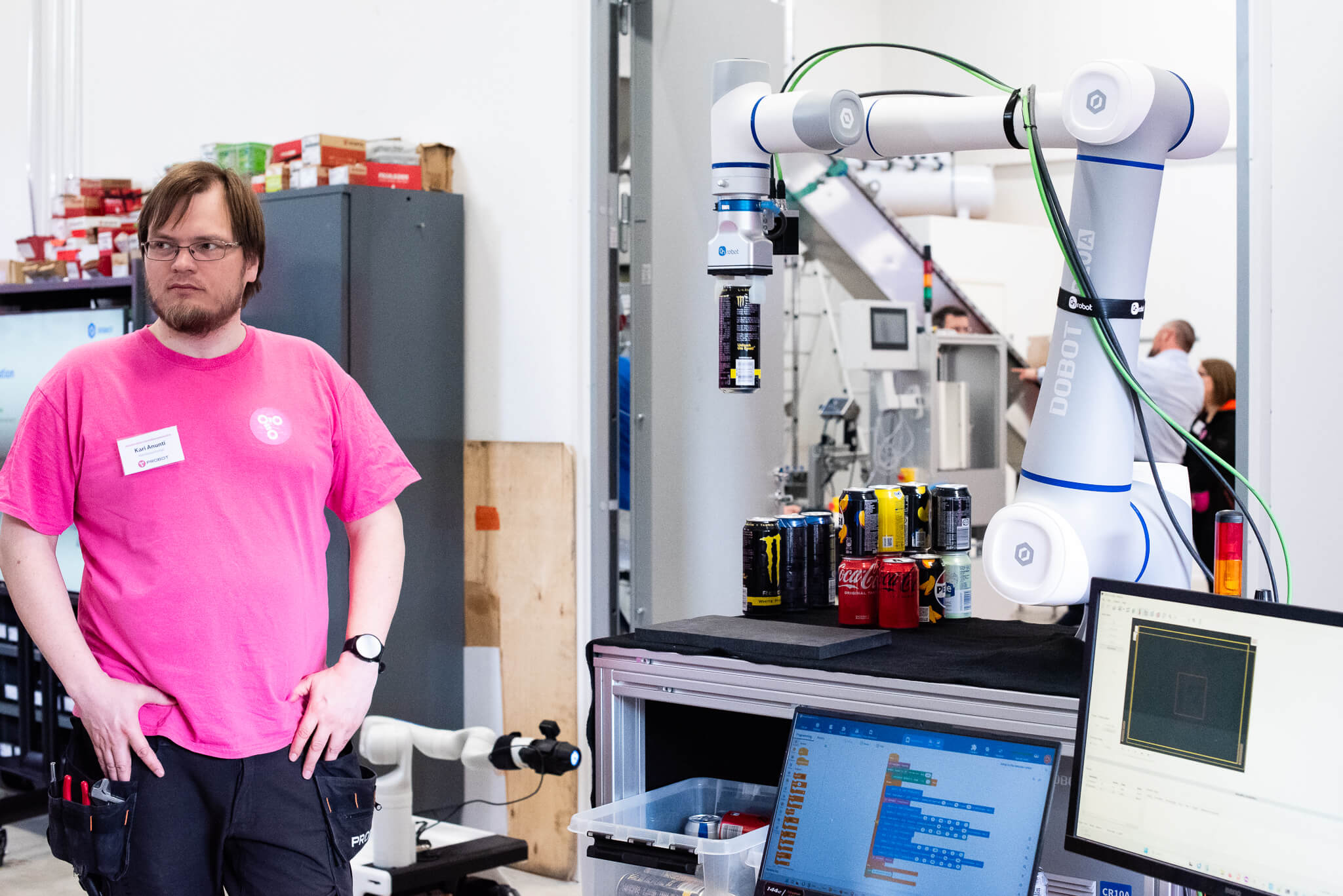

Our partner Murri Oy showcased Dobot collaborative robots and the SensoPart VISOR® series of machine vision sensors at the event. Murri’s experts Sami Kervola, Vesa Luoma and Jyrki Haapala were on site answering questions and demonstrating real-world applications across various industries.

At our Kempele facility, we presented two new Dobot collaborative robots, one of which was equipped with SafeSkin safety technology. This add-on enhances human–robot interaction by detecting obstacles and stopping the robot safely before physical contact occurs.

The Dobots attracted plenty of interest, particularly regarding their programmability and ease of integration. They are well suited for both industrial and educational use. The CRA-IP68 series meets the highest industry standards for water and dust resistance, making it ideal for even the most demanding environments.

AI-Powered Machine Vision in Production

In addition to Dobots, Murri Oy also presented SensoPart VISOR® machine vision sensors, including the new VISOR® Object AI model.

VISOR® Object AI uses machine learning to identify and classify parts in production. It can distinguish up to 200 different object classes and improves its accuracy continuously over time. The system integrates seamlessly into existing production environments, enhancing both precision and efficiency.

To demonstrate this in action, Probot’s expert Kari built a live demo combining a Dobot collaborative robot with a VISOR® Object AI camera. The AI identified objects in real time, and the robot responded accordingly.

Food Packaging Automation in Focus – Introducing a Fully Automated Bagging and Sewing Cell

One of the key attractions of the event was Probot’s fully automated bagging and sewing cell for food products. The system accurately dispenses food into paper bags, sews the bags shut with thread, and adds essential markings such as best-before dates or batch numbers.

The solution meets several current production needs:

- Increased automation: the system manages the entire packaging process accurately and independently.

- Plastic-free and sustainable: the system uses 100% fiber-based, recyclable paper bags and complies with tightening EU regulations (such as the PPWR). Demand for sustainable packaging solutions continues to grow as consumers and businesses seek more ecological alternatives.

- Scalability: the modular system adapts to different product and bag sizes, with a maximum package weight of four kilograms.

- Support for SMEs: the system is specifically designed for SMEs looking to streamline their production cost-effectively.

The system’s precise dosing mechanism helps reduce overpacking and saves raw materials. Sewing the bags closed provides a durable and safe closure without chemical adhesives or multilayer materials. This makes the solution especially suitable for SMEs looking for efficient and environmentally friendly packaging options.

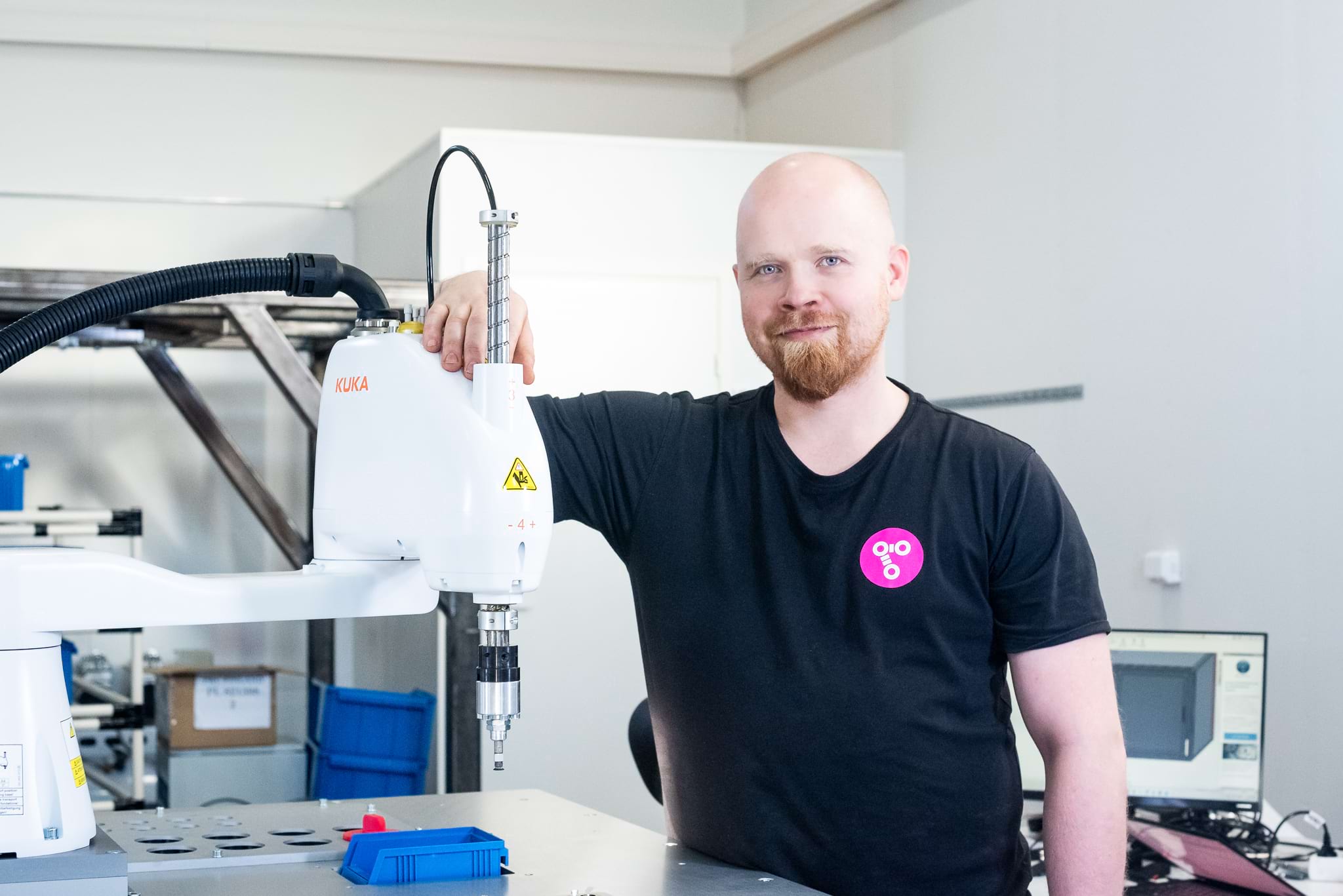

Mobile Robotics Made in Finland – Dolly™ and Taistelulaituri

At the event, we also showcased some of our own mobile robotics solutions. Dolly™ is a compact and agile mobile robot designed for indoor logistics, research applications and mobile manipulation. It performs well in tight spaces and is suitable for both indoor and outdoor environments. You can read more about Dolly™ here.

Taistelulaituri, on the other hand, is designed for outdoor logistics and transporting heavier loads. Despite its unusual name (which loosely translates as “Battle Dock”), it’s a reliable mobile robotics concept that has even been used in robotics competitions.

Conversations About Customer Needs and Future Solutions

Representing Probot at the event were CEO Matti, Sales Manager Maria, and our specialists Kari, Mika and Risto. Kari was responsible for the machine vision demo and presented the Taistelulaituri concept. Mika introduced visitors to the operation of our automated bagging and sewing cell, and Risto served as an expert on both Dobots and SafeSkin technology. Several other members of the Probot team also dropped by during the day.

Throughout the event, we had many in-depth discussions about the production challenges our customers face – and what kinds of solutions robotics, AI and automation can offer. The day once again highlighted how powerful it is to bring together technology, expertise and practical value in one place.

– This event happened to take place almost exactly two years after our last open house, so maybe we can call it a tradition already, Matti joked.

Perhaps we’ll meet again at our facility in a couple of years!

Thank You for Joining Us – Let’s Keep Building the Future Together

A heartfelt thank-you to everyone who participated in the event – and especially to Murri’s experts Sami, Vesa and Jyrki. It was a pleasure to organize an event where technology and practical applications truly came together.

If you’d like to learn more about our automation solutions for food production, mobile robotics or collaborative robots, feel free to reach out via our contact form here.

🔗 Explore our solutions, expert services and products here.

Probot Oy – Specialist in Robotics.