Contact us

Mobility expands robot applications

Although we’ve pretty much lost our hearts to robotics and automation, mobile robotics is our number one passion! We design and produce various mobile robots that move automatically on wheels. We provide solutions to both outdoor and indoor spaces and for transporting various loads. We’re also integrating OMRON and KUKA mobile robots into our production. We’re also your Unitree Robotics robot dog distributor in Europe.

We’d love to be your partner if you wish to investigate the opportunities mobile robotics could bring to your operations.

Versatile mobile robots

Our range (we’ve heard it’s pretty impressive!)

Customised solutions

Based on your needs, we develop and customise wheeled mobile platforms for outdoor and indoor use.

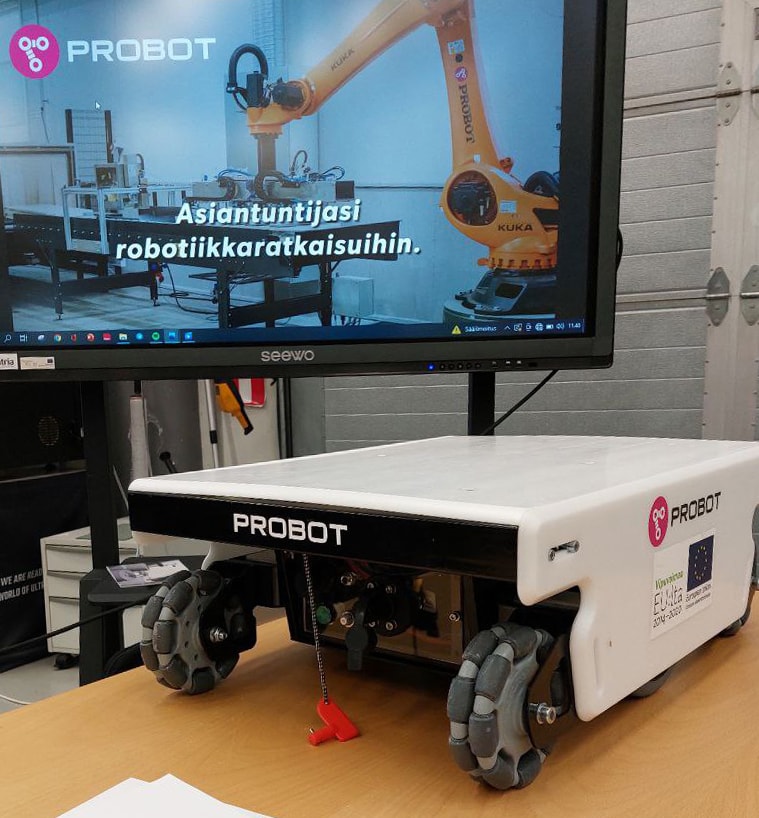

Versatile Dolly™

Developed by us, Dolly™ is a customisable mobile robot also suitable for logistics solutions in industrial environments.

OMRON™ mobile robots

We’re an OMRON Certified Partner. This means that our product range also includes OMRON™ mobile robots.

KUKA mobile robots

We’re also a KUKA Official System Partner. Our product range also includes heavy-duty KUKA mobile robots.

Unitree robot dogs and the humanoid robots

Mobile robotics with either two legs or four paws.

Let's make robots mobile!

We have a passion.

We find that it’s a pleasure to be passionate about what you’re doing. Our passion lies in mobile robotics – or should we say MobileProbotics. In fact, we believe that the next generation of robotics and its efficient utilisation will be based on robot mobility.

As its name suggests, mobile robotics means making automation mobile. This allows considerably expanding robot applications. In the extreme case, you’ll have access to the entire air space, terrain and, in increasing amounts, also bodies of water. Various sensors that enable making observations on the environment, such as cameras and lasers, can also be installed in mobile robots. They enable mobile robots to avoid obstacles and give way to people.

Our genuine and deep passion for mobile robotics has been a major factor influencing our work right from the start of establishing the company. This passion is reflected in our day-to-day operations: We offer a variety of mobile robot platforms that we utilise in the concepts we create for our customers. We’re also involved in developing mobile robotics in Europe and are active in participating in various EU projects and international robotics competitions to stay on the cutting edge of mobile robotics. We also closely collaborate with the Biomimetics and Intelligent Systems Group (BISG) at the University of Oulu to develop mobile robotics.

Intralogistics solutions

Automated intralogistics

The use of automated intralogistics is becoming rapidly more common. Robotics enable the smooth and safe transfer of goods, for instance in production facilities and storage spaces. In fact, useful mobile robots have been designed to also optimise indoor logistics processes that are heavy, repetitive, monotonous or dangerous to humans.

In this context, intralogistics does not refer to the operations of a single robot but instead forms a standalone entity. Safety and security, task management, situation picture and integration into the environment are also significantly related to intralogistics.

Mobile robots for outdoor applications

Outdoor robots

In practice, outdoor robotics involves similar automation as any automation implemented in an indoor space. However, the key to outdoor robotics is that everything is affected by the prevailing weather conditions, and the robot may have to move in a challenging terrain.

Outdoor robotics can be utilised in contexts such as logistics, field robotics and crisis management tasks.

Quadruped mobile robot

Robot dog

A robot dog is a mobile robot that moves on four legs by walking, running or even dancing. New applications for mobile robots are constantly emerging. Don’t let the sympathetic appearance fool you – this is much more than just a toy. The robot dog has versatile uses, for instance in indoor and outdoor logistics and in various guarding, inspection and detection tasks. A quadruped mobile robot can go where you can’t go with wheels.

Fully programmable

Unitree G1 – A Commercial Humanoid Robot Built for Real-World Tasks

Unitree G1 brings the power of AI into the physical world. It is a versatile development platform widely used in research, education and a broad range of application projects. Its precise mobility, advanced perception and strong onboard computing make it a practical tool even in real operational environments.

Scewo BRO

More than an electric wheelchair

BRO combines the comfort of a traditional electric wheelchair with the freedom of stair-climbing technology. The wheelchair’s smart features stabilize the movement and eliminate the need for torso stability. The height-adjustable seat allows you to pick up items from shelves, have a conversation at eye level or even sip a drink at the bar. Two large wheels ensure a stable ride on varying surfaces and the small turning radius makes BRO agile too.

Mobile robotics FAQ

In addition to carrying goods, mobile robots can push carts and pull trolleys. When passing through an environment, the robot can create a map of its surroundings, and a tablet or computer can be used to help it navigate. The robots are often programmed to move automatically on a specific route where they can perform various tasks. These tasks may include transporting goods or delivering empty parcels to specific places.

Just like other forms of robotics and automation, mobile robots can free humans from work tasks that are too dangerous and tiring, to focus on tasks that are more humane. Fewer and fewer people are interested in work that is too heavy and repetitive. The automation and optimisation of production have a positive impact on employee well-being and ergonomics as well as production efficiency.

There may be a significant decline in employees’ repetitive strain injuries and sickness absences when the heaviest work tasks are performed by a robot. Agile and enduring mobile robots can work every day of the year, at any time of the day. This means that it won’t take long until the mobile robot has paid for itself. Performing regular maintenance and following service instructions ensures that the robot will keep working in the long haul.

Various sensors that enable making observations on the environment, such as cameras and lasers, can be installed in mobile robots. They enable the robots to avoid obstacles and give way to people. This means that you don’t necessarily have to designate an area or pathway for the robot, but it can work in the same space with your employees.

Even though mobile robots can avoid bumping into obstacles, they may not be able to move them. This means that your factory must have employees trained in operating the robot. Human assistance may be necessary, for example, when the robot encounters an obstacle and there is no way for it to go around the object.

You may think that a mobile robot is too difficult and complicated to use. Actually, learning to use most mobile robots is fast and easy, and it’s worth training several employees on it. Robot programming includes teaching it paths and tasks, and you can add new ones or delete them as necessary. As a result, you can use a mobile robot for many different tasks based on your production needs.

The robot system can be integrated into production, and automation enables the robot to perform tasks in the desired order. The robot operates around the clock and recharges itself when its battery is running low.

Getting a robot is a good idea if your production process includes tasks that humans find monotonous, repetitive, consuming and heavy. If the aim is to improve accuracy, speed and even quality and promote well-being at work, you’re sure to benefit from a robot. You should think about which tasks you could designate for the robot and which ones would allow you to make use of your employees’ potential in a more humane way.

Depending on the content of the automated task, we can recommend a mobile robot, industrial robot or cobot (see our blog post: Collaborative robot or industrial robot). Here at Probot, we create robotics and automation solutions tailored to your specific needs.