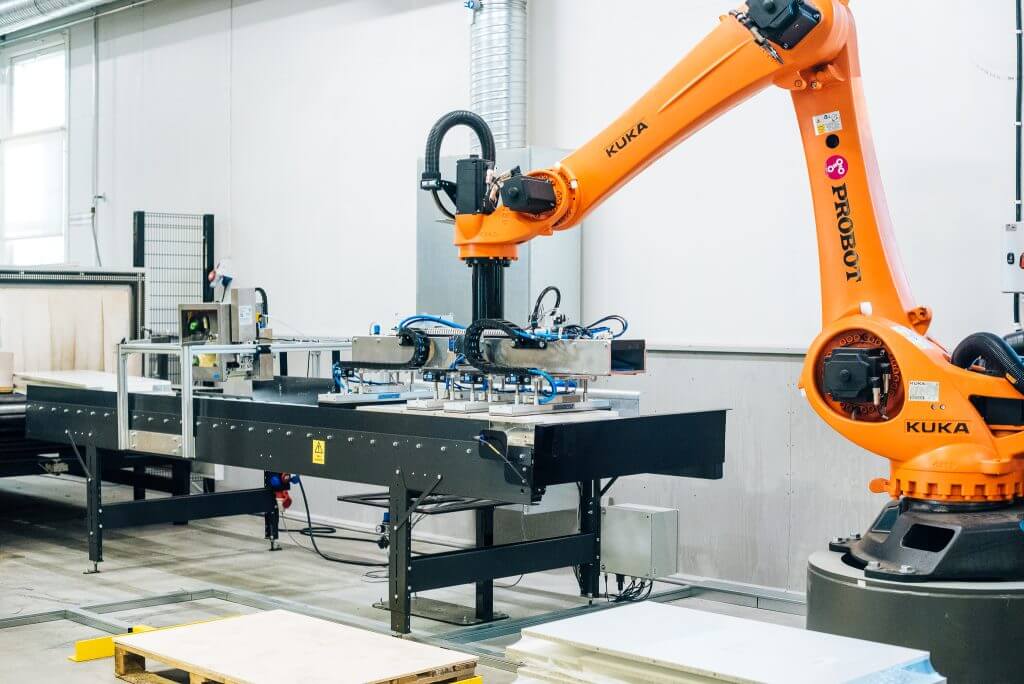

Robotic Cells

We produce robotic cells from start to finish for various industrial sectors. Our skills in designing the system as a whole, designing and manufacturing tools and our strong software competence enable us to carry out versatile projects. We offer all work stages under one roof. We build the necessary automation around the robot, provide custom user interfaces and implement control systems based on your needs.

Probotics that meets your needs

How to get started?

We always look at the solutions as a part of a bigger whole. We select a robot or cobot that meets your need and create entire systems for a variety of needs.

1

Selecting the robot

We start by selecting a robot based on its application: an industrial robot, a mobile robot or a collaborative robot?

2

Selecting and designing a gripper

Based on requirement specifications, the robot is equipped with a suitable gripper or tool.

3

Examining peripheral devices

We examine, automatise and program the necessary peripheral devices.

4

Additional design and building

We design and implement solutions such as device frames, safety guards, machine vision, platform equipment and jigs based on your needs.

5

Programming and implementation

We manage everything from data transfers between the different devices in a robotic cell to comprehensive manufacturing execution system integrations.

6

Quality assurance

We perform manufacturing execution system integrations and product marking. We’ll only settle for the best, so our solutions naturally also include quality assurance.

Any questions? Give us a call!

Let’s get your project up and running!