What is the difference between a collaborative robot or an industrial robot? When production automation is topical, you should map out what kind of robot fits your needs. A fast and powerful industrial robot or a small and agile collaborative robot?

Automation of the production process is increasingly relevant and necessary. In a modernizing world, time is of the essence, and production must be efficient. Work well-being and ergonomics are invested in even more. It is no longer ideal to work day after day in bad conditions and with a sore back. Even newly hired employees quickly change jobs if the working conditions are not modern. Outsourcing heavy, dangerous, dirty, and repetitive work tasks to robots free people for more human and creative tasks.

An Efficient Industrial Robot

Industrial robots are typically large, fixed machines designed for tasks that require high accuracy, speed and power. A robot is programmed for one task and is usually not transferred to another task. They are often placed in a carefully considered place, which is not easily moved after installation. There are models of industrial robots that can also be attached to the ceiling, wall, or track. Ensuring safety must be done carefully. Traditional protective fences or various lasers can be used for security, which ensures that a person cannot get into the working area of the moving robot.

The installation and programming of an industrial robot require expertise in the field. The robot is programmed and deployed by a professional who is also able to integrate the robot with other production equipment and machines. Mass-produced robots usually do not have tools ready, as they are always selected according to the intended use.

Industrial robots are available in multiple size categories. For example, robotic arms are available in models with a load-carrying capacity ranging from one to several thousand kilograms.

For these reasons, industrial robots are optimal for repetitive processes that remain unchanged for years and/or are dangerous to humans. The best benefits occur in routine tasks that require strength, accuracy and speed, such as palletising, assembly, machine tending and welding.

Cobot the Co-worker

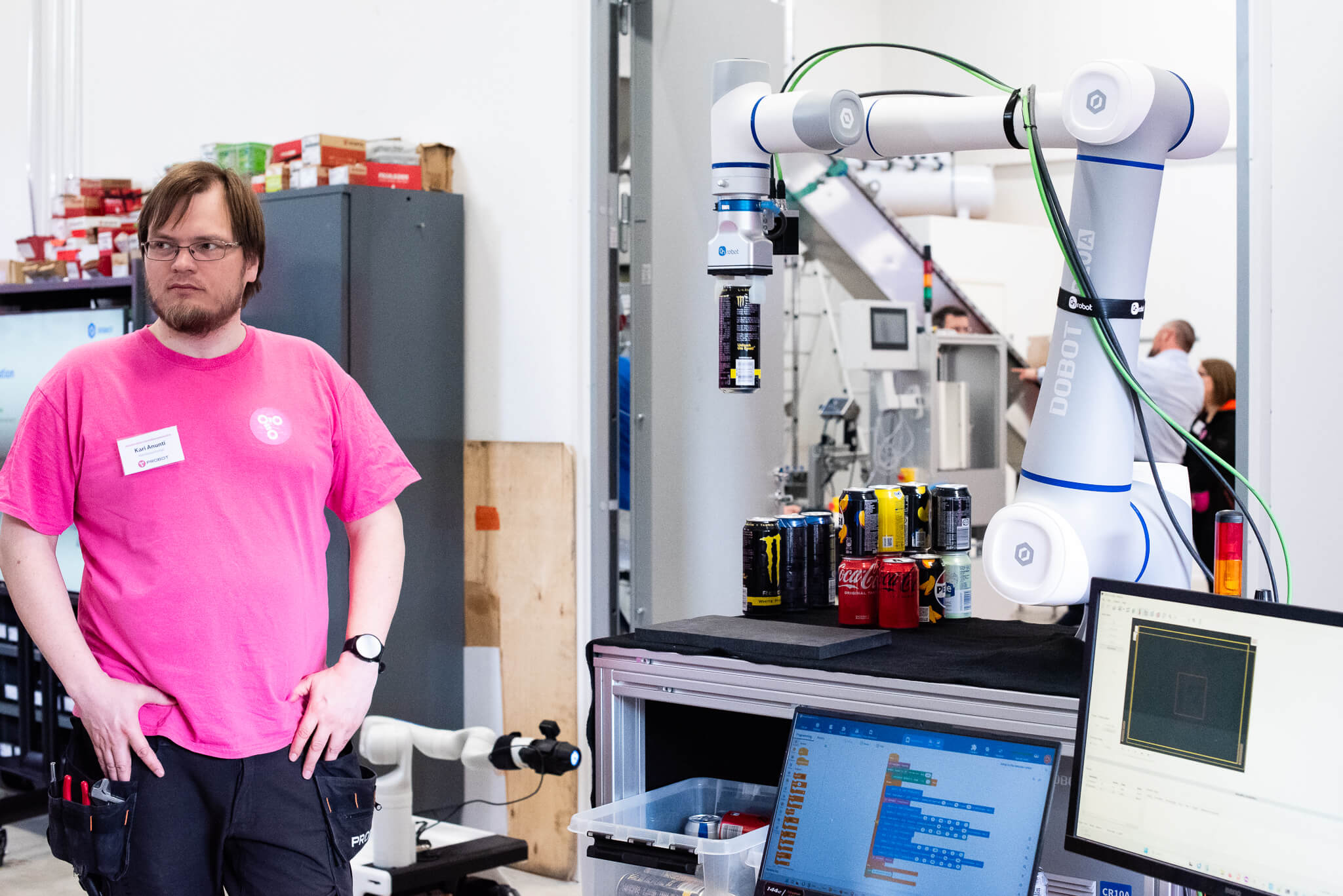

Cobots, or collaborative robots, are small and agile. They have been designed to support and enhance work processes and operate alongside human workers.

The calm and careful cobots do not need to be supported by safety arrangements – they stop when bumping into an obstacle. Just like an industrial robot, you can attach a cobot to a track, mobile platform or ceiling. However, as cobots are small, they can be alternated considerably more freely and they don’t take up a lot of space. The typical load handling capacity is quite small, usually under 20 kg.

Cobots are quick to learn new motions, and they are easy to program without special programming skills. The introduction of robots can cause doubts and reluctance in work communities where they have not been used before. Thanks to the ease of use of cobots, they are an excellent way to introduce automation to working communities. Collaborative robots are used, for example, in laboratories, quality control, assembly, and packaging.

When purchasing Cobot devices, you should ask for a trial run. It is good to find out, for example, what kind of additional equipment is available and how updates and possible maintenance are performed. Cobots can also be rented. In addition to familiarizing yourself with the alternatives, it is important to involve and familiarise the employees already in the implementation phase.

A Collaborative Robot or an Industrial Robot? Both Have Their Place

Industrial robots are therefore fast, powerful, and precise robots. They are best suited for repetitive, heavy processes that remain the same for years. Cobots are light, agile, and easy-to-use collaborative robots. They are best suited alongside people to support and enhance various work processes.

So, both robots have their place and don’t cancel each other out. The most important thing is that the solutions are customized to your needs.

Involving Employees in the Process

When considering the choice of a robot, you should pay particular attention to the content and needs of the process to be automated. Open discussion and participation with the entire staff help to map the needs and alleviate the friction of transitioning to a new way of working.

A common presupposition is that robots will take people’s jobs. However, we think that there are robot jobs and human jobs. Employees can move from the repetitive, health-threatening, and heavy processes in production into more humane and creative tasks, such as quality control and planning. This way, the company gets the most out of its resources, and the employees’ well-being increases.

Let’s bring robots into work communities!

You Can Read About Other Interesting Topics from Our Blog:

Probot Oy – Specialist in Robotics.