Mobile robotics will undoubtedly change the industrial playground. Although the use of mobile robots in domestic industry is still limited, their role in modern production and logistics will be significant. Therefore, mobile robotics is definitely an investment in the future. Mobile robots not only make current operations more efficient, but also pave the way for future innovation and development.

Mobile robotics, as the name suggests, means providing automation with mobility. This further extends the usability of the robot. Mobile robots can move autonomously, navigate their environment and perform tasks completely independently. Autonomous mobile robots are equipped with a variety of sensors that enable them to sense the environment and avoid obstacles and people. This increases their safety and usability.

Mobile robotics can offer numerous benefits across industries and revolutionise the industrial playground. However, it is not just about versatile automated solutions, as mobile robots offer much broader benefits regardless of the industry. But in a nutshell, what are the three most important reasons to get a mobile robot?

1. Mobile Robots Increase the Flexibility of Production

In a fast-changing industrial world, companies need to be able to react immediately to market changes to remain competitive. This requires flexibility and scalability of production processes and technology, as changes can be sudden and unpredictable. Order backlogs can fluctuate significantly in a short period of time. A sudden increase in demand may require a rapid increase in production capacity, while a fall in demand may lead to the need to adjust production downwards. Market trends and changing customer needs may require a company to change its production focus or develop new products. Order volumes and requirements may also vary widely, with some orders being for large batches and others for small quantities of customised products. Such changes require the company to be able to scale up its production, thus increasing its flexibility. Mobile robots often meet this need better than fixed solutions.

Mobile robots can adapt quickly to changing environments and tasks without fixed infrastructure, fences or tracks. They can move freely in factory and warehouse environments, adapting to different situations and avoiding obstacles when necessary. As production changes, mobile robots can easily be taught new tasks and environments. They have the ability to communicate and integrate seamlessly with other production systems. Autonomous mobile robots can also work collaboratively, i.e. in cooperation with humans.

Mobile robots are ideal for tasks that require flexibility, precision and autonomy in smaller spaces or confined access routes. Mobile robots are particularly useful in areas such as warehouse management, material handling and transport automation. They also work well in environmental monitoring and in various measurement and safety tasks where continuous monitoring and response to potential hazards are required.

The high scalability and adaptability of mobile robots allows them to operate for a long time despite changing production needs. Mobile robotics is not just a tool to improve the efficiency of current operations, but a key to production flexibility and meeting future challenges.

2. Mobile Robots Boost Production Efficiency

Mobile robotics will lead to more efficient, flexible and competitive operations in industry by enabling a wide range of solutions to reduce waste in line with LEAN principles.

There are many skills and attributes that humans can bring to their work that are not cost-effective for robots or that require creative problem-solving. Mobile robotics should be applied to tasks that do not exploit the potential of humans. These include, for example, various transport tasks. In this case, the skills and abilities of workers can be used more optimally. By automating the transport of materials from one factory to another or between different stages of the production line, robots can also reduce unnecessary movement and waiting.

Mobile robots can perform certain tasks faster, more accurately and without breaks than humans. This reduces waiting times and ensures the right materials are available at the right time, improving productivity. Autonomous mobile robots can check the stock situation, organise products and optimise the use of warehouse space. Inventory turnover rates are improved by reducing the storage of excess material and speeding up access to needed parts or components. Robotics also minimises the risk of human error and improves accuracy.

Mobile robotics enables flexible and real-time production optimisation, as robots can be used for data processing and analysis. Mobile robots can collect data on inventory, work progress and production line efficiency and feed this information in real time into a factory information system. This allows production to be adjusted to meet actual demand, reducing the risk of overproduction. Improving the flexibility of production lines also reduces unnecessary work.

Thanks to their scalability and adaptability, mobile robots have a long lifespan despite changing production needs. They can be integrated into existing systems, reducing costs and accelerating productivity gains. Therefore, a mobile robot can pay for itself very quickly.

Mobile robotics therefore enables waste to be minimised and thus allows for more efficient and economical operations. Mobile robotics is at the heart of modern industry and will continue to grow in importance in the future.

3. Mobile Robots Improve Workplace Safety and Employee Retention Rates

Like robotics in general, mobile robotics improves safety and ergonomics at work. It has a positive impact on employee motivation, which improves job retention.

Traditionally, workers in industry are exposed to physical strain and injuries, particularly as a result of heavy lifting and repetitive movements. By delegating such tasks to mobile robots, work-related risks, injuries and sick leave can be eliminated.

Mobile robotics can also help avoid human exposure to hazardous or harmful chemicals, as the handling and transport of such substances can be preferably left to the robot. Mobile robots can also operate in environments that could be hazardous to humans.

The introduction of mobile robotics in industry not only reduces physical strain, but also frees workers from repetitive routine tasks to more creative and problem-solving tasks. This not only improves the overall job satisfaction of employees, but also enhances their skills and commitment to the company. When employees feel that their work is meaningful and that they have the opportunity to develop, their motivation and commitment also improves. This can significantly improve a company’s competitiveness.

Mobile Robot is a Handy Partner

Mobile robotics has always been a passion for our team, and over the years we have delved into its benefits in many different ways. We’ve seen and tested, as well as designed and built, a wide range of mobile robots of all shapes and sizes. However, we found that there is a lack of a mobile robot on the market that has a good carrying capacity, but is compact in size and perfect in terms of programmability and customisability. So we decided to roll up our sleeves and create our own solution. That’s how Dolly™ was born.

Dolly™ is designed, developed and manufactured in Finland, more specifically in our own facilities in Oulu. This agile and customisable mobile robot is ideally suited for different logistics environments, such as factories, and can work safely with people in the same spaces. In addition, Dolly™ is also ideal for various research experiments and swarm robotics applications.

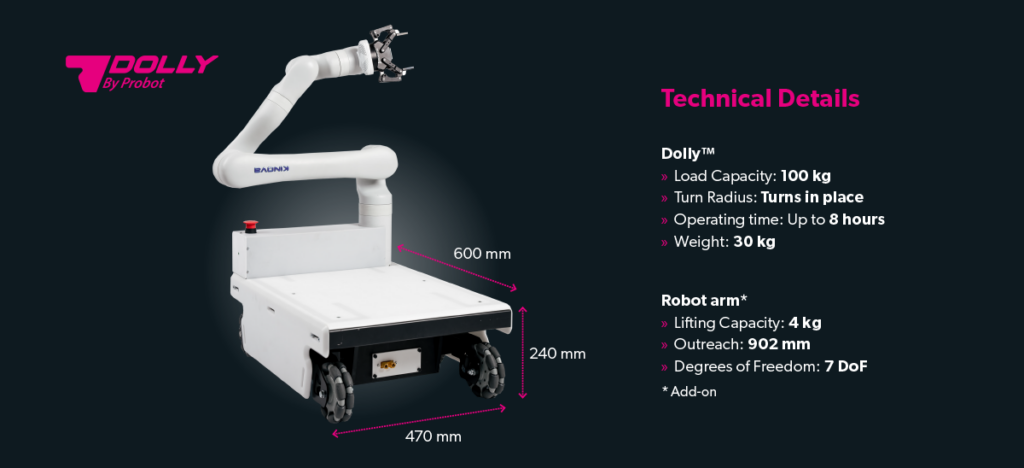

In the development of the Dolly™, we have paid particular attention to its agile navigation in confined spaces. It takes up only as much space as a person’s shoulders when moving and turns smoothly in place. Even small ramps and thresholds are not too much of a challenge for Dolly™, and it moves agilely outdoors. Despite its small size (470 x 240 x 600 mm), the Dolly can carry a whopping 100 kilos and operate for up to eight hours.

Dolly™ is a truly versatile companion for a variety of tasks.

Are you inspired by mobile robots?

Give us a call or drop us a message and let’s talk more!

Learn more about mobile robotics:

- Watch Dolly’s demonstration video.

- Get to know Dolly better.

- Learn more about our passion for mobile robotics.

- Are you worried about robots taking people’s jobs?

Read our blog on the subject.

Probot Oy – Specialist in Robotics.