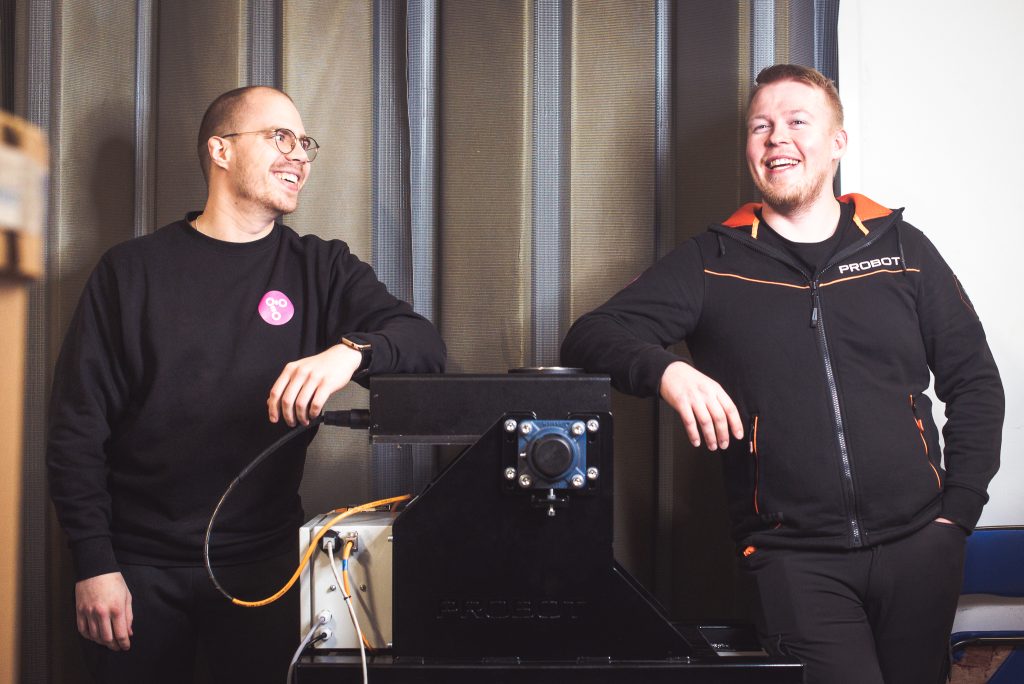

Probot Oy, which is opening a new assembly hall in Kempele at the end of the year, signed a cooperation agreement on 7.10. with the Kempele-based Cajo Technologies Oy. Both companies supply both directly integrated and stand-alone equipment solutions to industrial manufacturers.

In addition to their proximity, the companies also share a large customer base and the cooperation enables them to offer a wider range of products and services to their customers.

This cooperation will allow industrial manufacturers to benefit from a comprehensive

production efficiency solution, combining cutting-edge branding, precise machine vision and

reliable robotic automation.

– It’s great to start working with such an innovative and young company, whose branding is the real technology of the future! It allows us to offer our customers an efficient, environmentally friendly and traceable solution for branding almost any material, Matti Tikanmäki, CEO of Probot Oy, is delighted.

– In addition, Cajo and Probot share a progressive approach to traditional industries.

We look forward to working together on new projects!

– Working together with Probot, we are achieving significant added value for material producers and

and downstream processors, as well as component and end-product manufacturers. There is a growing need in the manufacturing industry for solutions that can increase the degree of automation of production processes, improve product quality and increase cost efficiency through the most environmentally friendly methods possible.

Today’s production, logistics and processing chains require the most accurate and real-time quality management and monitoring of material flows. Regulatory requirements for product traceability are also becoming increasingly stringent, Niko Karsikas, CEO of Cajo says.

Cajo is an international, fast-growing technology company with headquarters and manufacturing

Kempele, with subsidiaries in India and the United States and supplies to over 60 countries, including market leaders in the metal, automotive and cable industries.

The company provides optimised and easy-to-use total solutions for industrial production processes for traceability and product labelling. The long-lasting and maintenance-free solutions have been developed to replace traditional marking methods such as inkjet, print, sticker, engraving, etching and painting technologies, among others.

The technology enables machine-readable traceability markings that last through

product lifecycle, even under challenging conditions. Cajo’s laser technology achieves a carbon footprint reduction of more than 90% compared to, for example, inkjet marking due to the technology’s additive-free nature.

Probot Oy, a provider of customised robotics and automation solutions for various industries, is experiencing a period of strong growth. The Oulu-based specialist company has solid experience in various industrial robot cells and mobile and collaborative robot solutions. Probot’s customers are mainly small and medium-sized production plants from various industries. The company was founded in 2006 and currently employs 20 people. As a KUKA System Partner, OMRON Certified Partner and European distributor of Unitree’s robot dog, Probot Oy wants to be a pioneer in robotics in Finland.

The solutions implemented by Probot Oy can be tailored as part of a larger whole. From prototyping to the finished product, implementation is possible under one roof and on a turnkey basis. Machine vision, artificial intelligence and augmented reality (XR) capabilities are also available where required.

Automation of the production process is becoming increasingly relevant and necessary. Today, robotics is a highly functional and reliable solution that quickly pays for itself. At Probot, we believe that technology can be applied to almost anything and has the potential to solve workplace challenges in many traditional sectors. Probot acts as a consultative partner to the client, providing insight into what technology can do. Basically, everything can be automated.

Probot Oy – Specialist in Robotics.