Is an 8-hour workday still enough to keep up with orders? Are lifting tasks causing sick leave? Wondering whether robotics or a robotic cell is even worth the investment?

Many manufacturing and production managers will recognise the scenario. Finnish SMEs are struggling with labour shortages while advances in technology have made robotics more affordable. If you’ve been considering a robot but have hesitated due to costs, staff reactions, or technical complexity, you’re not alone. The same questions land on the table daily: Is it worth the investment? How will our team react? And will this actually bring value to our business?

Why an industrial robot is a strategic move for SMEs right now

Finnish industry and logistics are going through a major transformation. Labour shortages, rising wages, increasing production costs, and the need for flexible processes are all putting pressure on SMEs. On top of that come quality requirements, workplace safety regulations, and delivery reliability.

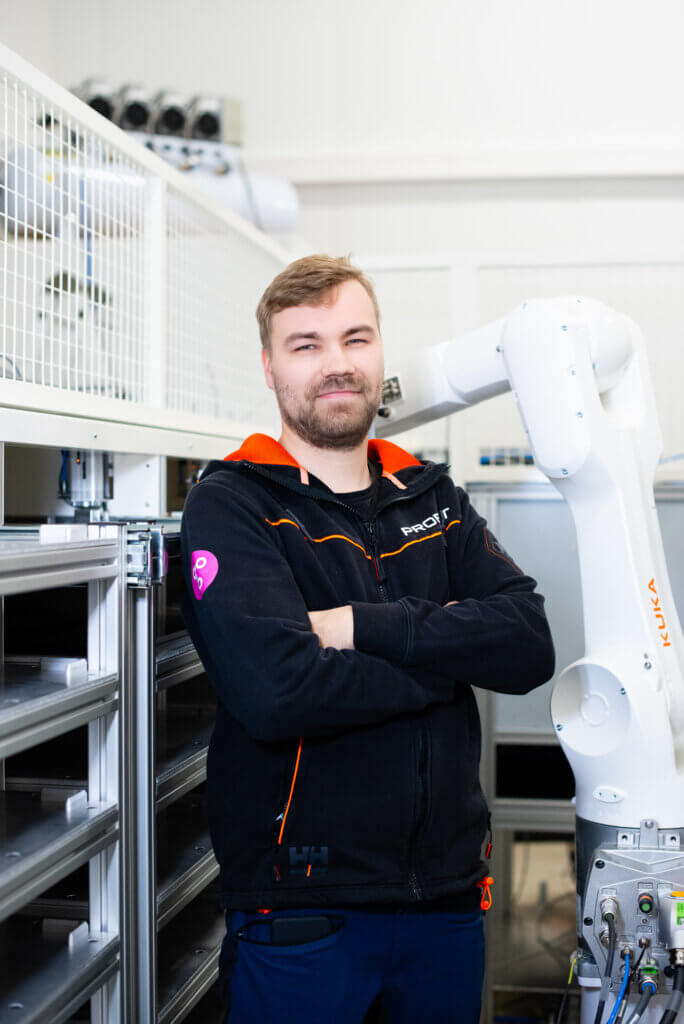

At Probot, we see industrial robotics as a strategic investment for the entire production chain. When heavy, repetitive, and ergonomically challenging tasks are shifted to robots, people can focus on what they do best – like creative problem-solving and process development. Robotics doesn’t replace humans, it completes the team.

As we like to say: There are jobs for humans and jobs for robots.

Customer Case: Turning waste into a valuable resource with a smart robotic cell

Together with our customer, we developed a smart robotic cell that uses machine vision to sort leftover pieces from the sawing process, enabling efficient reuse.

The solution proved so effective that the investment will pay itself back in about 2.5 years. The robotic cell reduces costs, supports the company’s sustainability goals, and delivers a significant competitive advantage. Automation not only boosts current production efficiency. It also lays a strong foundation for future development projects.

The project required engineering sweat, cross-disciplinary expertise, and close collaboration, but the end result was exactly what the customer was aiming for:

“The robot is impressive and works exactly as intended. I believe it’s a tool well worth the investment.”

Read the full story on how an industrial robot turned material waste into a valuable resource:

Customer case here.

Why a robotics solution is more than just a piece of equipment

Many robotics suppliers will deliver a machine and wish you good luck. We, on the other hand, support you in the entire design and implementation process:

- We identify your real needs together with you, analysing bottlenecks and automation opportunities.

- We design a solution that fits seamlessly into your existing processes, review it with you, and refine it as needed.

- We handle commissioning, training, and lifecycle support and optimise the solution if needed.

Three reasons to automate your production now

- Local automation expertise is world-class and easily available in Finland.

- Robotics technology has advanced: solutions are now more flexible and cost-efficient than ever.

- An investment in automation can address both labour availability and competitiveness challenges.

How to get started with an industrial robot purchase

Our Robot Buying Guide gives you the first stepping stones:

- When it’s the right time to invest.

- Which tasks robots are best suited for.

- How to successfully navigate the process from planning to commissioning.

Grab a cup of coffee, check out our Robot Buying Guide, and take your first step towards more efficient, safer, and more competitive production. Who knows – that very first step could be your winning edge.

Probot Oy – Specialist in Robotics.