On February 25th we will be at the Radisson Blu Hotel in Oulu, at the Northern Freeze event!

The SME Guide to Buying a Robot – Tips for a Successful Automation Project

Thinking about investing in a robot but not quite sure about the payback period? Wondering how your team might respond to automation? This practical ABC of industrial robotics gives small and medium-sized businesses a clear roadmap to a profitable and successful automation project.

You can jump straight to the section that interests you using the table of contents below – or simply scroll down and explore the full guide step by step.

INTRODUCTION

Why automation matters right now

PART 1

Applications and Profitability

PART 2

Understanding the Technology

PART 3

Investment and Implementation

PART 4

From Insight to Action

Introduction

How to succeed in automation on your first try

Thinking about adding a robot to your production, but not sure where to start? You’re not alone. Many SMEs are asking the same questions: How much does it cost? Could a robot even handle this task? How will the team react? And most importantly – is it even worth it?

This guide gives you a clear overview of what it really takes to get started with robotics, and what kind of value it can bring. We’ll walk you through when automation makes sense, where robots work best in SMEs, which technical decisions are worth understanding, and how to carry the whole project across the finish line.

This is version 1.0 of our Robot Buyer’s Guide – but certainly not the last. Robotics evolves fast, and so does this guide. This page won’t be gathering dust: we’re updating the content regularly, so it’s worth checking back now and then. A downloadable PDF version is also in the works. Stay tuned!

Why now is a great time to get into robotics?

Finnish manufacturing is undergoing a major transformation. A shortage of skilled workers, rising costs, and the demand for more flexible production are pushing companies to seek new solutions. At the same time, safety, quality, and delivery reliability are more critical than ever.

Robotics offers concrete answers to these challenges:

- Frees up staff from repetitive tasks

- Improves consistency and reduces waste

- Brings flexibility, stability, and predictability to production

- Increases safety in physically demanding or hazardous tasks

- At the same time, robotics supports business growth and strengthens Finland’s competitiveness

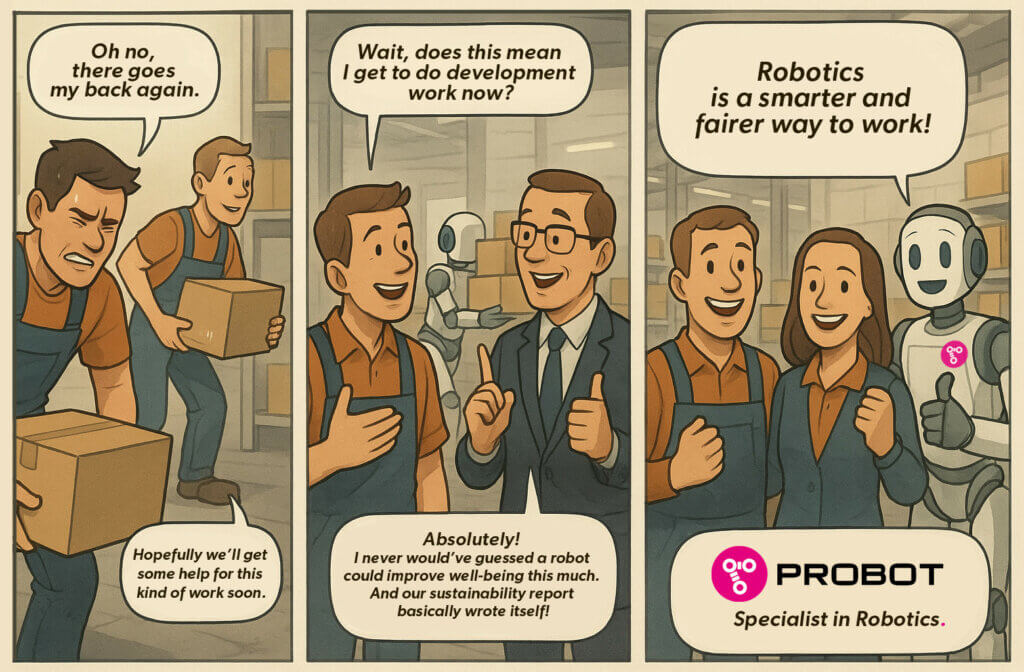

But robotics is more than just boosting efficiency. Automation can also be human-centered. Investing in better well-being and ergonomics isn’t just a nice idea – it’s a real, measurable benefit that shows up in fewer sick days and longer careers. When robots handle the heavy, repetitive work, people can shift to more varied, lighter, and more meaningful tasks.

SMEs need solutions that scale – and robotics makes that possible without endlessly increasing headcount. Even though Finland is a highly advanced tech country, we’re still at an early stage when it comes to adopting robotics. That’s an untapped competitive edge just waiting to be claimed.

It’s also worth remembering: a successful robotics project starts with involving your people. When employees are part of the process from day one, automation becomes a shared opportunity – not a threat. That’s when the whole team wins.

Robotics is no longer just for the big players. Thanks to rapid technological development, flexible, modular, and easy-to-deploy robotic solutions are now available for SMEs too. Robotics is an investment that pays off – both in business results and workplace well-being.

And most importantly: robotics doesn’t just make work more efficient – it makes it smarter and fairer. When robots take care of the routines, people can focus on what they do best. At the same time, your processes start generating transparent data almost automatically. Plus, you’ll save energy, backs, and delivery deadlines. Robotics might just be one of the most tangible ways to advance your sustainability efforts.

PART 1: Applications and Profitability

When does a robotics investment make sense?

Robotics can step in when your production needs a boost – whether it’s about efficiency, quality, or flexibility. But it’s not always the right time to jump in. Here are some signs that your operation might actually have meaningful work for a robot.

Production pain points

- Skilled workers are hard to find for repetitive tasks

- One slow step is holding back the entire process

- Manual work leads to quality issues and customer complaints

- Too much material is wasted

- Lead times are nearly impossible to predict

Business development needs

- Costs are spiraling (energy, materials, wages)

- Productivity needs to increase without a hiring spree

- Growth and exports demand better delivery reliability

- Variable orders and small batches require more flexibility

- Production continuity is at risk due to external factors

Improving the work environment and driving sustainability

- Too many tasks are dangerous, heavy, or physically straining

- Absenteeism and employee well-being are ongoing concerns

- Sustainability goals demand more efficient use of resources

Technical realities

- Space is limited, but output needs to grow

- Old automation systems are due for an upgrade

- Digitalization and broader automation are the logical next step

Sound familiar?

If even one of these hits home, it might be the right time to take a closer look at what automation can offer.

Where robots actually help in SMEs

Robots make the most sense when they deliver immediate value and are relatively easy to implement. In small and medium-sized manufacturing, that often means tasks like these:

Material handling and internal logistics

- Handling heavy parts: Lifting, moving and machine loading – let the robot take the strain off your team’s backs.

- Automating part feeding and removal: Robots can deliver parts into the cell and move finished products forward in the process.

- Internal factory transport: Mobile robots move items from point A to B, no one has to walk alongside.

Machine tending and production processes

- Machine tending: CNC machines, injection molding machines, and other production equipment get a reliable assistant in a robot.

- Repetitive tasks: Robots love routine work like welding, assembly, gluing, and surface treatment.

- Linking processes: Automatic handoffs between production steps mean no more waiting between stages.

Quality, finishing, and packaging

- Packaging and sorting: Robots organize, pack, and group products without ever tiring.

- Quality control: With machine vision, a robot can spot defects more precisely than tired human eyes.

- Finishing tasks: Grinding, polishing, and cleaning are handled smoothly and consistently.

Special applications

- Ergonomically challenging work: Robots are built for repetitive lifting and awkward movements.

- Hazardous tasks: Toxic materials and risky processes are no problem for a robot.

- Precision work: A robot’s hand stays steady, even on a Friday afternoon.

Flexible, production-enhancing applications

- Small batches: Easily programmable robots adapt quickly to product changes.

- Eliminating bottlenecks: Robots are perfect for removing slow points that hold up the line.

- Adjusting capacity: In peak production periods, robots help scale output without extra staff.

When you assign a robot to tasks where it actually saves time, nerves, or money, daily operations start running that much smoother. People can focus on what they do best. And when automation is applied in the right place, the payback time is often surprisingly short. Some jobs are for people. Some are for robots.

Is your company ready for robotics?

Quick-readiness checklist for SMEs

Thinking about adding a robot to your factory? Excellent! You don’t need a perfect process or a sparkling new facility. What matters most is the drive to improve your production. Just a few basic things are enough to get planning started. We can help assess your situation and move forward with you, one step at a time.

1

Is your process robot-ready?

- Are work instructions documented, or only stored in your most experienced employees’ heads? Robots need clear, repeatable processes.

- Does the process stay more or less the same from week to week? Robots can handle small batches if there’s some consistency. If every production run is completely different and never repeated, programming might become a bottleneck.

- Do you collect production data, or go with your gut? Without measurement, it’s hard to know whether the robot is doing its job.

- Do you know where your production gets stuck? Robots should be placed where they eliminate real bottlenecks.

2

From a production point of view

- Are there repetitive, boring tasks? Robots love those.

- Do employees perform hazardous or physically demanding work? Robots are more than happy to take that on.

- Do materials flow logically or take the scenic route? A clear material flow makes robot integration easier.

- Is there a lot of waste in tasks that require precision? A robot’s hand doesn’t get tired or shaky.

3

Attitude makes all the difference

- Is your leadership in it for the long haul or just looking for quick wins? Robotics is a marathon, not a sprint.

- Do you have someone in-house who owns the robotics project and is eager to drive it forward?

- Do key people react to new tech with curiosity or fear? Either way, reading this guide might help!

4

Involve your team from the start

- Are you planning to involve employees from day one? Early engagement means less resistance later.

- Is the robot seen as a job stealer or as a way to ditch boring tasks?

- Who’ll keep the robot up and running day-to-day? Machines need care and a little friendship, just like people do.

5

The technical environment

- Will your IT systems cooperate with the robot, or are they as stubborn as a mule?

- Do you have in-house technical know-how – or is using a USB drive already a challenge?

- Any experience with tech projects? Past success is a good predictor of future wins.

6

Factory layout and physical space

- Can the robot even fit through the door? (Not a joke – we really ask this.)

- Can materials be delivered easily to the robot, or do they have to be moved manually? We can implement transport solutions, but they’ll affect the scope and cost.

- Is safety taken care of – or is the robot expected to operate like it’s the Wild West?

7

The financial reality

- Do you have the courage to invest in a system with a 1–3-year payback time?

- Can you see the big picture – or just the price tag?

- Do you know how to measure the payback time? A robot brings more than just euros – it can also improve quality and well-being. Those can have a financial impact too, through fewer errors and absences.

8

Choosing the right partner

- Do you have a reliable partner lined up – someone who understands both the tech and your industry?

- How will you ensure support and maintenance once the robot’s in place?

- Have you explored funding options? Many organizations actively support digitalization.

Not quite sure yet?

No worries! Your robotics readiness grows with every step you take. And we’ll be right here with you the whole way.

Smart automation = smart business

The right robots in the right places

Still unsure about your robotics readiness? No worries! Readiness grows step by step, and you don’t have to get everything perfect from the start. If you already have a clear direction, you’re well on your way. We’ll help you identify those critical points where a robot delivers the most value without flipping your entire factory upside down. Smart automation means using the right tool to serve the right goal.

Today, almost anything is technically possible – and often at a reasonable cost. But just because something can be done doesn’t mean it should be done. Successful robotics isn’t about what technology can do. It’s about what actually makes sense to automate.

Always remember: a robot isn’t the solution in itself – it’s a tool to help you reach your goals. Technology provides the means, but the direction comes from you. Once you know where you’re going, the robot helps you get there.

PART 2: Understanding the Technology

Get to know the different robot types

There’s a robot for almost every purpose, and the right type depends on what you’re trying to achieve. Here’s an overview of the most common industrial robot types and where they typically shine.

Articulated robots

Versatile, general-purpose robots.

Features:

- Typically 6–7 DoF (degrees of freedom – axes of movement)

- Flexible 3D motion

- Wide reach and complex movements

- Available in a range of sizes

Typical applications:

- Konepalvelu (työstökoneiden lataus ja purku)

- Hitsaus, ruiskuvalu, liimaus

- Kokoonpano ja komponenttien käsittely

- Hionta ja pintakäsittely

Advantages: versatility, flexibility, long reach

Challenges: takes up space and requires full safety integration

SCARA robots

Fast and precise.

Features:

- Cylindrical working area

- Extremely fast and accurate

- Limited mobility (mainly in the x-y plane)

- Compact design

Typical applications:

- Electronics assembly

- Pick-and-place operations

- Screwing and fastening

- Precise handling of small components

Advantages: speed, precision, cost-efficiency

Challenges: limited reach and mobility, usually suitable only for light parts

Delta robots

Lightning-fast and lightweight.

Features:

- Ultra-fast movement

- Typically mounted upside down above a production line

- Lightweight structure with parallel arms

- Limited working area

Typical applications:

- High-speed pick and place

- Handling food and packaging

- Sorting and packing

- Assembly in high-speed applications

Advantages: unmatched speed, accuracy

Challenges: limited reach and payload, requires elevated installation

Collaborative robots (cobots)

Designed for working safely alongside humans and easy to use.

Features:

- Built for safe human–robot collaboration

- Built-in safety features (force limits, collision detection)

- Easier programming, often teachable by demonstration

- Typically for lighter payloads (max. 10–20 kg)

Note: While cobots are designed to be safe, simply using a cobot doesn’t make an application safe by default. Safety must always be assessed for the whole system and working environment. For example, moving loads, sharp tools, or high speeds can introduce risks that require additional protection or evaluation.

Typical applications:

- Light part handling and assembly

- Quality inspection

- Pick and place

- Packing and palletizing

Advantages: ease of use, quick deployment, minimal space requirements, collaborative capabilities

Challenges: limited speed and payload

Mobile robots

They navigate on their own, no guidance needed. They roll, walk, fly, or even swim. In industrial settings, common applications include logistics, inspection, and monitoring. And at Probot, we’re especially into mobile robotics.

Features:

- Move autonomously in production environments

- Navigation via laser scanners, cameras, or landmarks

- Can be equipped with various loading or sensing tools

Typical applications:

- Material transport in production

- Warehouse automation

- Transporting products between workstations

- Condition monitoring and routine measurements

- Integrable into a wider automation system

Advantages: flexibility, scalability, no need for fixed structures

Challenges: navigation in complex environments, battery limitations

What’s in a robot cell – key components and their roles

A robot never works alone. It’s part of a larger system where different components support one another. The whole setup only works efficiently when every part is carefully selected and designed to fit the needs of the specific application. Below is an overview of the key elements in a robot cell.

End-of-arm tools and grippers

Grippers make it possible for a robot to grab and move parts. Common options include mechanical clamps, vacuum grippers, and magnetic solutions. Designing the right gripper is critical for ensuring production accuracy and reliability.

End-of-arm tools define what the robot actually does – whether it’s welding, grinding, screwing, or measuring. Tools are attached to the robot’s flange, and in some applications, robots can even change tools automatically during operation.

Feeders and conveyors

For a robot to operate effectively, it needs continuous access to the parts it handles. Feeders and conveyors ensure a smooth material flow into the robot cell and move finished products out. They play a central role in maintaining production efficiency and enabling automation.

Machine vision and sensors

Precision and intelligence come from sensing technology.

Machine vision allows robots to detect the location and characteristics of parts.

Sensors give the system responsiveness: for example, force, touch, or presence sensors can be used for quality control or safety.

Software and interface

The robot cell is controlled through software and user interfaces.

The interface allows operators to manage the entire cell, integrating all components into a single control environment.

Software enables production control, process monitoring, and data collection for analysis. A well-designed interface makes managing the system smooth and transparent.

Safety systems

Safety isn’t an add-on – it’s the foundation of every robot cell. Common solutions include light curtains, safety fences, emergency stop buttons, safety relays, and speed limiters. A safety system must consider both the potential risks robots pose to humans and how human actions might affect the robots’ operation.

A well-functioning system

A well-designed robot cell is more than just the sum of its parts. When all components work together seamlessly, the result is like a healthy organism: each element supports the others, timing is precise, and the whole system performs its tasks efficiently without interruptions.

At its best, a robot cell is efficient, reliable, and stays operational year after year with proper maintenance.

Master the technical facts before choosing your robot

Choosing the right robot is crucial for the success of the entire project. That’s why it’s important to understand a few key technical factors early on. Here are the most important ones to keep in mind from the start.

Payload capacity

Payload capacity tells you how much weight a robot can handle safely and reliably. But it’s not just about the weight of the part – you also need to consider the following:

- The weight of the gripper or tool

- Movement speed and acceleration

- Load variations during the process

- The center of mass – that is, how far the load’s center of gravity is from the robot flange. The further away it is, the more torque is applied to the robot, which can significantly limit the usable payload.

That’s why it’s usually recommended to leave a safety margin of about 20–30% when selecting a robot. For example, if the total load (including gripper) is 10 kg and the center of mass is well beyond the flange, it’s safer to choose a robot with at least a 13 kg capacity or more if reach or motion paths add further challenges.

Reach

Reach refers to the area within which the robot can operate. Too little reach may prevent access to certain tasks, while excessive reach can lead to unnecessary cost. You should also consider the size of the tools and any physical obstacles in the work area.

Accuracy and repeatability

Your robot doesn’t need surgical precision in every task – but in some applications, even a few millimeters can make a difference. Especially in assembly and quality control, repeatability (how well the robot returns to the same point) is often more important than absolute accuracy.

Speed and motion smoothness

Maximum speed is like a car’s top speed – nice to have, but rarely critical in everyday use. In production, it’s overall cycle efficiency that matters most. Optimizing movements and avoiding unnecessary travel typically have more impact than peak speed alone. In collaborative robots, speed is intentionally limited for safety.

Control and integration

A modern robot is not a standalone unit. It’s part of a larger production system. A good control system integrates smoothly with other systems, such as MES (Manufacturing Execution Systems) and ERP (Enterprise Resource Planning). This way, the robot can automatically receive tasks, report when they’re done, or pass on data for analysis.

Integration means the robot and its control system can communicate with other systems and devices – like machine vision, sensors, conveyors, or warehouse management. This enables fully automated and coordinated workflows without manual handoffs.

Operating environment

Production conditions matter. Is the space dusty, humid, or hot? The IP rating tells you how well the robot handles environmental factors. IP54 is enough for many applications, but in sectors like food production, IP67 or higher may be required.

Maintainability and lifecycle

When choosing a robot, it pays to look a bit further down the road. How easy is it to get spare parts? Is manufacturer support and software updates available?

The right robot in the right place

Choosing a robot isn’t about a single spec – it’s about the whole package, where all technical factors influence one another. We’ll help you get it right the first time, so your investment delivers optimal results from day one.

PART 3: Investment and Implementation

What many wonder before taking the leap into robotics

Doubts and questions are only natural when you’re considering new technology. In our experience, many SME owners wrestle with the same thoughts before deciding to bring a robot on board. We’ve collected the most common concerns we hear daily on the factory floor – along with answers that will hopefully help you move forward too.

FAQ: Frequently Asked Questions Before Making a Robotics Decision

It depends—much like the price of a house. Let us ask: what kind of house are you looking to build?

The cost of a robot investment depends on multiple factors: the application, required payload capacity, programming complexity, and necessary peripheral equipment. It’s not just about the robot itself, but rather the full system. The price typically includes the robot, grippers and tools, safety systems, planning and implementation, plus training and support. A precise price is difficult to give without a needs assessment, but a knowledgeable partner can offer a budget estimate. Keep in mind that early estimates are based on preliminary information and may change as specs evolve. Open discussion and a careful needs assessment are key to realistic budgeting. A good expert partner communicates this transparently throughout the process.

A well-designed robotics investment can pay for itself within 1–3 years. Much depends on the application and how accurately the benefits are recognized and measured.

For payback time calculations, it’s essential to identify all benefits, not just the obvious savings:

- Labor cost savings: Robots work around the clock, even on holidays, with no overtime pay. Reassigning even one operator to higher-value tasks can yield significant savings.

- Quality improvements: Robots perform the same task exactly the same way each time, reducing defects and increasing customer satisfaction.

- Reduced material waste: A more precise and repeatable process cuts waste, which can save significantly when expensive materials are used.

- Increased capacity: Robots don’t take coffee breaks and can run during off-hours, boosting overall throughput.

- Indirect benefits: Fewer sick days, reduced accident risk, and easier workforce management may be harder to quantify, but they are real benefits.

Example: If a €100,000 robot cell generates €40,000 in annual net benefit, the payback time is 2.5 years. Usually, actual savings exceed initial estimates.

Most likely yes, but first, we need a small assessment of your production.

Modern robot systems are far more flexible than many expect. They can handle variable products and small batch sizes—if products and processes have been properly analyzed. Tasks best suited for automation include repetitive and monotonous tasks, ergonomically burdensome lifts and transfers, precision assembly, and processes prone to human error. However, robotics may not be ideal in every scenario—very low volumes or constantly changing products can make automation challenging. A knowledgeable partner helps determine which tasks to automate first. We often begin with the “easiest ones,” allowing fast wins and learning before moving on to more complex applications.

Choose a robot based on the task, payload, precision, and available space, and involve an expert partner from the very beginning.

Selecting the right robot depends primarily on what you want to automate. There’s no such thing as “the best robot”. The ideal choice always depends on the demands of your process. Here are some key considerations:

- The task: Is it repetitive handling, welding, assembly, logistics? Different tasks call for different robot types.

- Payload and reach: How heavy are the objects, and over what distance do they need to be handled? These factors determine, for example, the size of an articulated robot or whether a collaborative robot is more suitable.

- Precision and speed: Do you need millimeter-level accuracy or lightning-fast pick-and-place? SCARA and delta robots excel in speed, while articulated robots offer versatility.

- Work environment: Are you working in a tight space, along a production line, or in a mobile setting? Mobile robots suit logistics, while cobots work safely alongside humans in shared spaces.

- Modularity and flexibility: Does the solution need to scale or adapt to new tasks over time?

For the best results, review the robot types and applications together with an expert. A skilled partner will not only understand your technical requirements but also your business goals, and recommend a solution that delivers long-term value.

Yes! Modern robots are versatile tools adaptable to many different needs.

Modern robotic systems are far more flexible than traditional fixed automation. Flexibility is reflected in areas such as:

- Reprogramming: Robots can be taught new tasks without major structural modifications.

- Interchangeable tools: The same robot can use different grippers, milling heads, cameras, or other tools for various tasks.

- Machine vision: Modern vision systems help robots identify and handle different parts without complex mechanical feeders.

Modularity means building the system in interchangeable components that can be reused, upgraded, or reconfigured as needed like building with Lego bricks. If you automate an assembly task today, tomorrow the same robot can be repurposed for packaging or machine tending. This flexibility extends the investment lifecycle and improves ROI.

Much easier than many expect. Forget the long code lines—modern interfaces are visual and intuitive.

“Can our employees actually operate the robot?” is a common concern. In reality, interfaces are user-friendly. Many tasks can be taught by demonstration, without traditional programming. A good partner provides pre-made program templates tailored to your needs. Most often, the operator only needs to adjust parameters or make simple selections. A reliable partner doesn’t just deliver the robot. They train staff in different roles, create accessible documentation and quick guides, provide post‑deployment support, and enable remote assistance so experts can help in real time, even across different locations.

In robotics, an operator is the person who actually runs the robot, not a telecom operator.

An operator works with the robot daily in production. Think of them like a vehicle driver—they might not know engine mechanics, but they handle operation smoothly. A robot cell operator may:

- Start and stop the robot

- Run simple programs

- Load materials and remove finished parts

- Adjust basic settings and address daily issues

- Perform quality checks and help optimize the process in collaboration with the robot

Operators don’t need engineering degrees or coding experience. Often, the best operators come from production—they know the process and the products and quickly learn to use the robot as a tool. Many such operators also offer valuable insights—spotting early ways to use the robot effectively or suggesting processes better suited for human work. Their role is crucial: they bridge technology and practical production, and their input is vital for continuous improvement.

Modern robots are extremely reliable—think of them as workhorses. They don’t complain of back pain or get tired.

Concerns about reliability and utilization are valid. No one wants an expensive decoration in their factory. In reality, modern robots are highly dependable:

- Mechanical durability: Designed for 24/7 use with a typical lifespan of 80,000–100,000 hours (10+ years of continuous operation).

- Predictive maintenance: Regular servicing and diagnostics catch potential issues before they cause downtime.

- Remote support and diagnostics: Many problems can be solved remotely—no technician needed onsite.

- Clear operating procedures: A good partner trains operators in troubleshooting common issues so minor problems don’t halt production.

In our experience, a well‑designed robot cell achieves a 95–98% uptime—often higher than manual operations. The most common reason for a robot “standing idle” is simply a lack of feed material—because it works so efficiently!

Robots are more adaptable than many imagine.

Space constraints are a common concern—especially for SMEs with already full production floors. But robot solutions can almost always fit into existing spaces:

- Cobots often require no more room than an operator workstation.

- Modular solutions can be configured to site conditions. Some robots can even hang from the ceiling to save floor space.

- Mobile systems let the same robot serve different workstations as needed.

- Deployment can be staged: start small and scale later.

The best results come when the robotics vendor collaborates with you to create a careful layout that considers material flows, workplace safety, and operator movement. Together, you’ll find the best adaptation—even in tight environments.

Engagement is key. When employees see the robot as a partner—not a replacement—their resistance often turns into enthusiasm.

It’s completely normal for robot introductions to spark conversation, even concern. In our experience, successful adoption hinges on involving staff from the start:

- Transparent communication: Clearly explain why automation is considered and what benefits are expected.

- Inclusive planning: Employees’ process expertise is invaluable. Inviting them into the decision process improves both outcomes and acceptance.

- Clear role definitions: Explain how roles change and how robot-assisted work enables more meaningful tasks.

- Training and support: Ensure everyone gets sufficient training and help using the new technology.

In truth, robots rarely take jobs. Instead, they transform jobs—shifting people away from monotonous, heavy, or risky work to more meaningful roles like inspection, troubleshooting, and development. We’ve seen many cases where initial doubts turn into excitement once people see how robots make their work easier and open new opportunities.

A cobot (collaborative robot) is designed to work with people—often without safety fences. Safety always depends on the specific application.

Cobots differ from traditional industrial robots in purpose, safety design, and programming approach. Both are used in industrial automation but suit different tasks and environments:

Traditional industrial robot:

- Built for speed, strength, and precision

- Requires safety fences

- Handles heavier payloads

- Usually faster

Collaborative robot (cobot):

- Designed to work safely alongside people

- Includes features like collision detection and force limits

- Often programmed manually by demonstration

- Suited to lighter payloads (typically under 20 kg)

- Requires less space and may not need safety barriers

Important: A cobot’s built-in safety doesn’t automatically make the entire application safe. Safety must always be evaluated system-wide, including tools, loads, motion paths, and environment. Choosing between cobot and industrial robot depends on your application needs, production process, and safety requirements. In some cases, the best solution combines both—a cobot for light interactive tasks and a traditional robot for heavy, repetitive work.

Safety is everything. Modern robots are strictly regulated and safe—if installed and used correctly.

Safety is the foundation of robotics. Industrial robotics adheres to strict standards (such as ISO 10218 and ISO/TS 15066) that ensure safe operation. Safety is ensured differently depending on robot type:

Traditional industrial robots:

- Safety fences prevent access to the robot’s workspace during operation

- Light curtains or scanners detect when someone enters the danger zone

- Safety mats and scanning systems monitor access zones

- Emergency stop buttons in strategic locations

Cobots:

- Force-limiting and collision detection stop the robot immediately on contact

- Speed limits ensure safety in shared workspaces

- Safety sensors and cameras monitor the area

Risk assessments define the necessary safety measures. All systems comply with the EU Machinery Directive and carry CE certification. A reliable partner always conducts a thorough risk analysis and ensures staff are trained in safe use.

Look for a partner who listens, asks questions, and focuses on solving YOUR challenges—NOT just selling equipment.

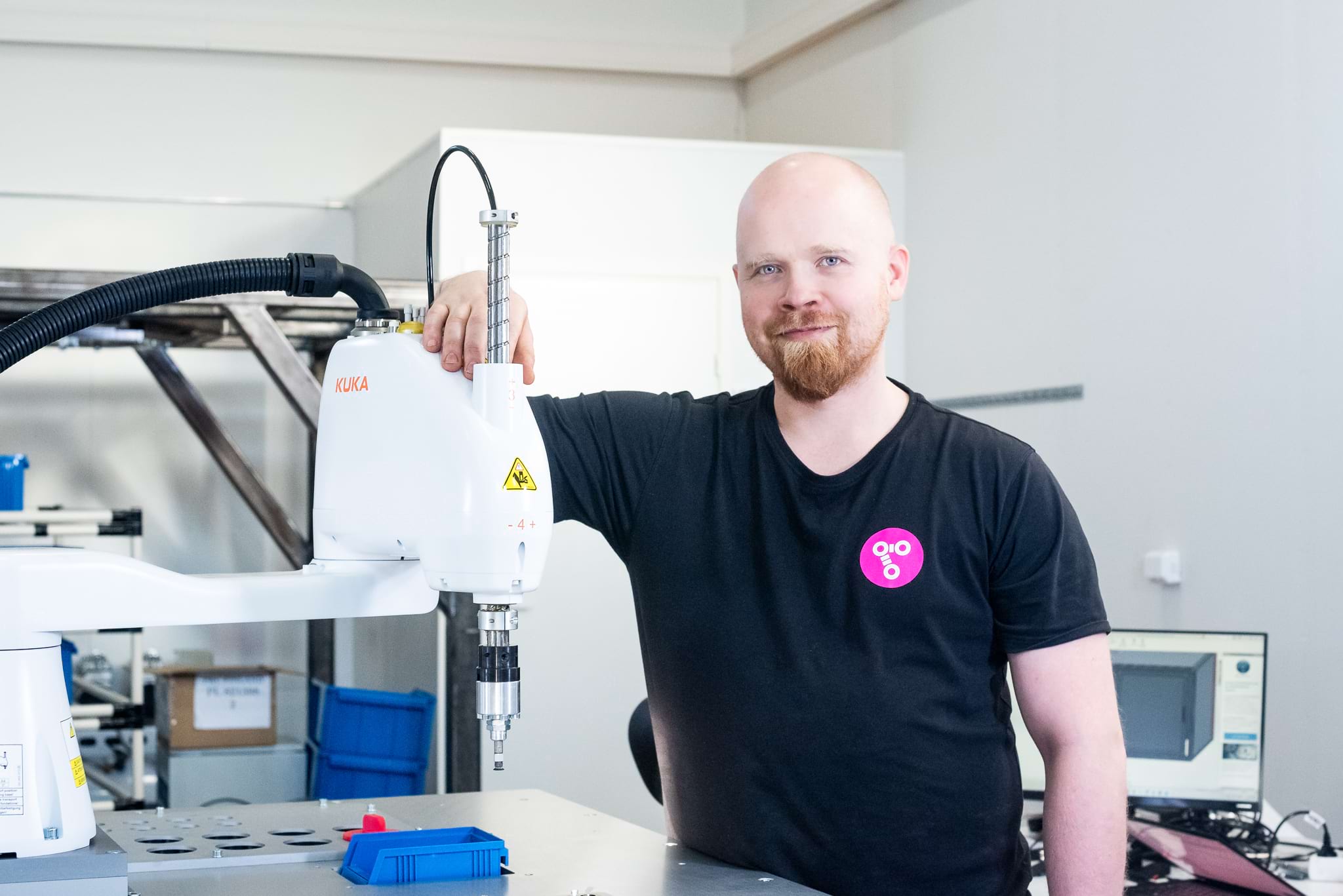

The robotics market includes a wide range of providers, and the choice of partner significantly affects project success. For your first robotics project, pay attention to:

Vendor vs. expert partner:

- A vendor sells the robot and basic installation

- An expert partner supports you from need identification through continuous improvement

Signs of a great partner:

- Ability to explain tech in accessible terms, without jargon

- Interest in your business and processes

- Clear project methodology and communication

- References from similar projects

- Ongoing post-deployment support

Questions worth asking:

- How does the process work—from idea to deployment and maintenance?

- What support services are available after implementation?

- Who do we call if something goes wrong?

- What is the lead time for spare parts or service?

For SMEs, we strongly recommend a partnership model where the supplier takes full ownership of the system—not just delivery. Trust is built through open communication, honesty, and shared successes.

What makes a successful robot project?

Even the best technology won’t do the trick on its own. A successful robotics project combines realistic goals, smart preparation, and people who are actively involved. These key principles separate triumphant rollouts from stumbling starts:

1

Plan more than you think you need.

Invest early in documenting processes, defining clear objectives, and evaluating your options. A well-thought plan is truly half the battle.

2

Set measurable, specific goals.

Think productivity gains, payback time, or even improved ergonomics. Clarity in your targets makes execution so much smoother.

3

Get the team involved from day one.

Projects imposed from above rarely spark enthusiasm. The most successful robotic initiatives are shared triumphs across the organization.

4

Choose a partner who speaks your language and gets your business.

A great partner isn’t just a supplier. They’re your strategist, planner, and coach. Especially when challenges arise.

5

Allow time… and then add a bit more.

Set realistic schedules that include testing, a learning curve, and a few surprises. First versions are rarely final.

6

Document what you’ll want to repeat.

Good documentation isn’t paperwork—it’s your playbook for the future. It helps in operation, onboarding, and continuous improvement.

Good to know!

Robotics doesn’t need to do everything at once. Real, meaningful results happen step by step.

A strong start lays the foundation for success and builds confidence in new technology. Each achieved milestone strengthens your company’s automation muscle.

We’re here for you every step of the way!

Our mission is to make sure your robotics investment delivers from day one. From planning through implementation and ongoing development—we’ve got you covered. Reach out, and let’s tailor the best solution together.

PART 4: From Insight to Action

How to get going? Here are your 5 first steps:

- Identify your pain points: Where is time, effort, or accuracy being wasted?

- Assess your opportunities: Which tasks could benefit most from automation?

- Evaluate readiness: Are your processes, space, and people ready for change?

- Map your resources: Do you have investment appetite, know-how, or partners to support you?

- Talk to an expert: Get a clearer picture of what to do next.

You don’t need a perfect plan, just the will to start. And when the time is right, we’ll be here to help.

Great job making it through the guide! Now you’ve earned your bonus!

Any lingering questions about robotics?

Is something on your mind? Probot’s experts are ready to help. Reach out anytime!

BONUS!

Probot‑Finnish Glossary: Understand what those engineers really mean

We couldn’t include a kitchen knife set with this guide like on teleshopping, but our glossary is almost just as sharp. Here’s a concise package of terms you’re likely to hear in the world of robotics. From now on, you’ll speak Probot‑fluent better than ever!

Robot types and systems

Robot

Officially: A programmable automation device.

Practically: The reason we get up in the morning. A small obsession, really.

Industrial robot

A traditional production robot that usually works apart from humans behind safety fences. Strong, fast, precise.

Collaborative robot (cobot)

A robot designed to work safely alongside humans, often without safety enclosures. Includes safety features like force detection and automatic slowdown.

Mobile robot

A robot that knows where to go and what to do without someone shouting orders. It moves autonomously in the workplace. Mobile robotics are a true passion for the Probot team!

Robot cell

The complete setup built around the robot, including safety systems and peripheral equipment.

AMR/AGV

Autonomous Mobile Robots / Automated Guided Vehicles used for material transport in production facilities.

Robot parts and tools

Gripper

The robot’s tool for grabbing the parts it works with. Can be mechanical clamps, vacuum grippers, or magnetic solutions.

Tool flange

The mounting point at the end of the robot arm where grippers and tools are attached.

TCP

Short for Tool Center Point—the precise reference point from which a robot’s movements are calculated. (Not “Time for Coffee Pause”—tempting, but no.)

Joints (axes)

The “joints” of a robot that allow movement in different directions.

Machine vision

A camera system that allows the robot to “see” and identify objects.

Performance & technical specs

Degrees of Freedom (DoF)

Number of independent movement axes. Industrial robots typically have 6 DoF.

Payload

The maximum total weight a robot can handle—includes its tool and the workpiece.

Reach

The distance a robot can reach while moving; important for determining workspace coverage.

Repeatability

A robot’s ability to return to the same point repeatedly—often more critical than absolute precision in many tasks.

Absolute accuracy

The ability to reach precisely the intended coordinate (less critical in many cases than repeatability).

Singularity

A condition where robot movement is restricted because its joints align in a limiting way—best avoided during programming.

Programming & operation

Online programming

Programming the robot directly on its controller in the production environment.

Offline programming

Programming via a separate computer with simulation—without disrupting production.

Teach‑in (manual programming)

Programming method where you physically guide the robot to desired positions. Also known as manual control or teach pendant programming.

User interface

The software and hardware through which the robot’s functions are controlled.

Integration

Process of connecting the robot to production systems and other equipment.

Robot integrator

A company or expert who designs, implements, and deploys robotic systems tailored to a customer’s needs—making the robot genuinely useful for the business, not just a hardware vendor. So where do you find Finland’s most charming integrator? Well, you’re already reading their guide 🤖

Safety

Safety zone

The robot’s guarded operating area protected by safety devices or fences.

Emergency stop (E‑stop)

A button or function that immediately stops the robot and entire cell in a dangerous situation.

Safety scanner / light curtain

Optical systems that prevent robot motion if a person crosses into the danger zone.

Dead‑man switch

A handheld safety device that must be pressed correctly for the robot to move during programming. Sounds morbid, but ensures the operator remains in control.

Collaborative zone

A designated area where humans and robots can work together safely.

Risk assessment

The evaluation process for identifying hazards in a robot system and planning mitigations.

Financial terms

ROI (Return on Investment)

Measure indicating how quickly a robotics investment pays for itself.

TCO (Total Cost of Ownership)

The full cost of a robot throughout its lifecycle, including the purchase price as well as operational and maintenance expenses.

Payback time

Time required for the benefits from a robot to offset its initial cost.

—

These terms are truly handy.

Understanding them makes robotics discussions clear and helps in making smarter decisions during the procurement process.

Final words

We hope this guide has given you a clearer view of what robotics can do and how to start your automation journey! We’ll continue to keep it fresh with new insights. Drop by regularly to stay ahead in the world of robotics.

If something makes you curious or raises a question, reach out anytime! We’re always ready to talk about how robotics can work for your business. Here’s to more efficient production! 🤖