In production and logistics, massive amounts of materials are constantly generated that need to be sorted quickly, safely, and as accurately as possible. This is where intelligent automation comes into play. But what exactly is it all about? We’ve gathered the top 5 questions and answered them with zero jargon – straight to the point.

1. How does intelligent material sorting differ from traditional methods?

Intelligent sorting utilizes automation, robotics, and machine vision. Materials are identified and separated automatically, resulting in fewer errors and a more efficient process. Additionally, the system collects data that helps in the long-term development of operations.

2. What are the benefits for the industry?

There are several advantages:

- Time savings, as less manual sorting is required

- Improved work safety, as physically demanding tasks are transferred to machines

- Increased sorting accuracy, reducing errors and waste

- Cost savings through optimized processes

Furthermore, the entire material flow becomes transparent, supporting more responsible and efficient decision-making.

3. Where does this solution work best?

Intelligent sorting is particularly suitable for the needs of environmental management, construction and demolition, logistics, and the metal industry. Solutions are always tailored to the specific application, making them highly versatile.

4. How easily can the solution be implemented?

Easily and painlessly. Probot partners with you throughout the project: we start with a situational analysis, requirements specification, and planning, proceed to implementation, and ensure functionality even after deployment. The solutions are modular and scalable, meaning they can be expanded or modified as production grows or needs change without having to rebuild the entire system from scratch.

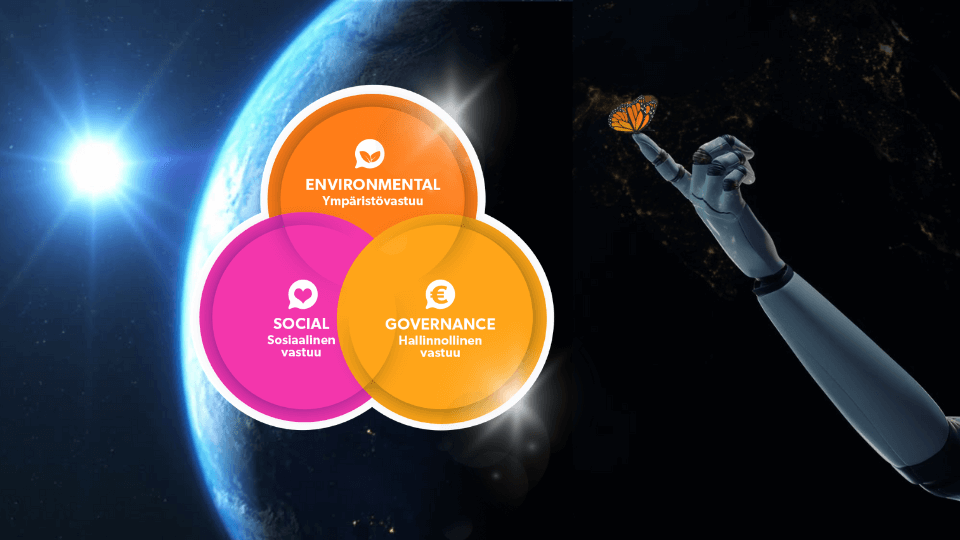

5. How does intelligent sorting support sustainable development?

This is an important question, and it deserves more than empty phrases. With more precise sorting, less material ends up in the wrong place. Recycling rates increase, unnecessary transportation decreases, and raw materials are conserved. The end result is a genuinely more resource-efficient and responsible operating model — not forced, but as a sensible part of the process.

Looking for a smarter sorting solution for your production?

If there are still manual steps in your material handling or if there’s room for improvement in sorting efficiency, let’s talk. We are ready to design and implement a solution that serves your specific process.

Contact us here, and let’s find out how much time and money you can save with intelligent material sorting!

Also, read more about our intelligent sorting solution in our expert blog here.

Probot Oy – Specialist in Robotics.