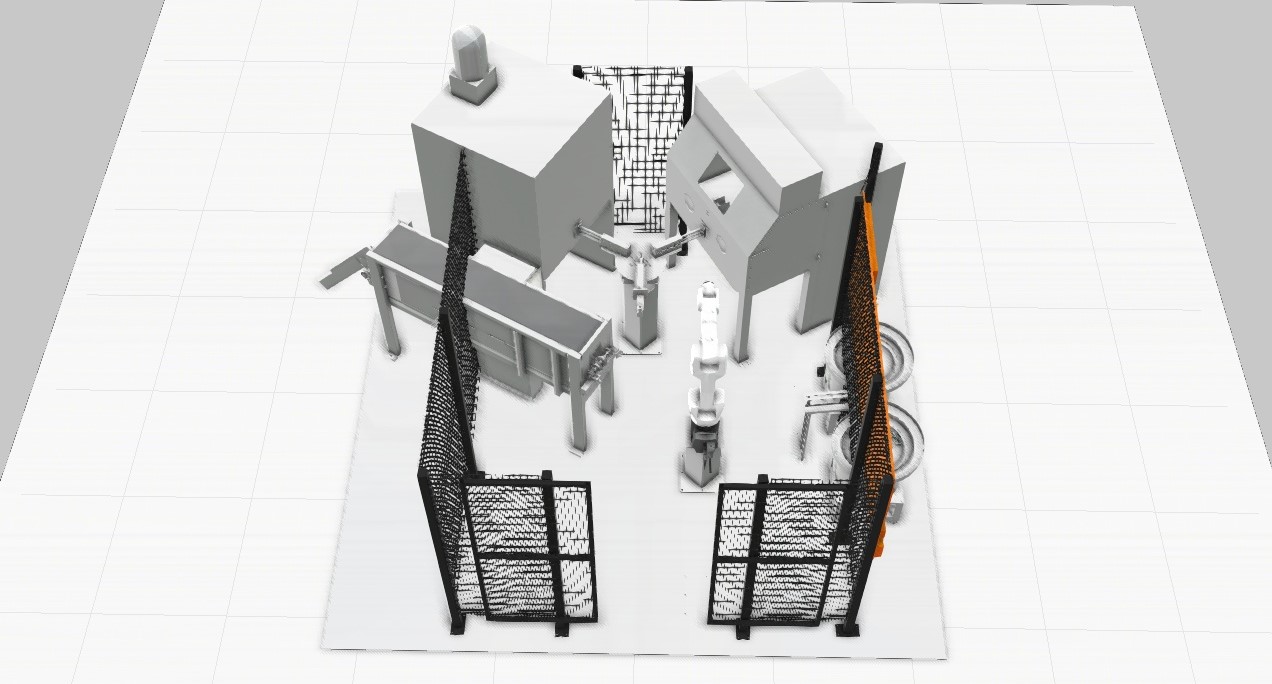

In the pre-processing cell system we delivered, a robot (Kuka KR10) operates an abrasive blast chamber and a coater unit using a rotary table. The robot picks objects from vibrating bowls and places them in jigs on the rotary table. The cylinders on the table push each object to be processed in turn. We modified the chambers and vibrations for automatic drive and for the processing of five different objects.

The service included everything from design to procurement, modification of chambers and vibrations, and the implementation, testing, installation and introduction of the work cycle and user interface. The control system was implemented using Beckhoff logic.